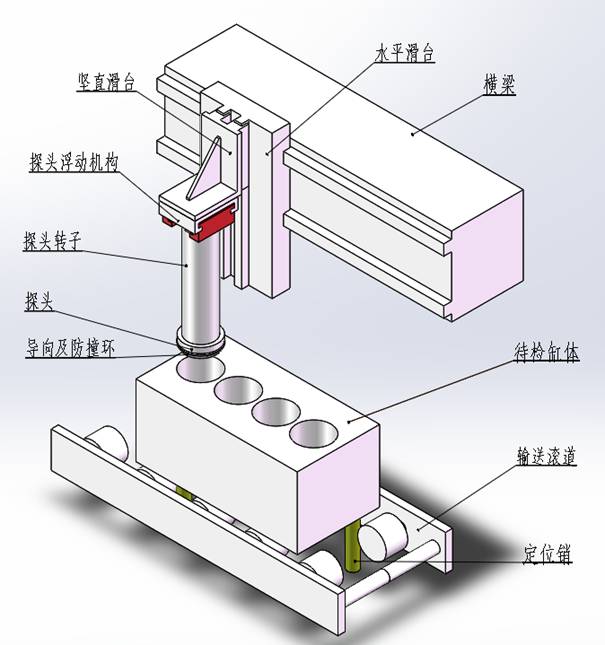

ET- F1 engine cylinder hole eddy current flaw detector

The equipment consists of instrument system, rotating probe system, probe servo system (including probe floating device), detection and positioning system, electrical control system, etc. In order to adapt to the possible large tolerance of shape and position, the device is designed with probe guiding device, collision avoidance device and probe floating device. This device allows the position tol...

PreviousNext OnlineProduct introduction

The equipment consists of instrument system, rotating probe system, probe servo system (including probe floating device), detection and positioning system, electrical control system, etc. In order to adapt to the possible large tolerance of shape and position, the device is designed with probe guiding device, collision avoidance device and probe floating device. This device allows the position tolerance of cylinder bore to positioning pin bore up to plus or minus 5mm. At the same time, the collision avoidance device can automatically start the stop procedure when the comprehensive tolerance between the position of the cylinder block and the positioning of the cylinder block exceeds this range, so as to avoid damaging the cylinder block and the equipment.

Core

◆Rotary probe system

It is the technical core of this equipment. Eddy current automatic detection requires a stable relative motion (scanning motion) between the detection probe and the surface of the product to be tested. The effective detection area of the probe is 1 mm*1 mm when the front end of the probe passes through the product to be inspected. Therefore, in order to achieve full coverage detection of cylinder inner surface, it is necessary to make the probe screw scanning on the cylinder inner surface. The rotating probe system of Bockner can be used in conjunction with the eddy current instrument system of Bockner to maximize the efficiency of the equipment. The Bockner rotating probe system has the characteristics of high speed, stable operation, reliable signal transmission and zero maintenance.

Summary

|

Cylinder size |

F1A:φ88mm*100mm(Bore diameter * cylinder center distance) |

|

|

F1C:φ95.8mm*110mm(Bore diameter * cylinder center distance) |

|

Check the accuracy |

Standard parts 0.5mm*0.5mm (deep*diameter) flat bottom hole |

| Cylinder number |

4 |

|

Detection mode |

Probe Rotator + Servo System |

|

Charging way |

Manual pallet feeding |

|

Detection mode |

Automatic manual switchable |

|

Charging way |

Manual |

|

Missing detection rate |

0% |

|

False positive rate |

5% |

|

Distance from cylinder bore inner wall |

0.5mm |

|

Radial Runout of Probe Rotator |

<0.05mm |

|

Detection cycle |

<300s(Feeding 5s + positioning 3s + scanning 140s + moving 100s between probe cylinder holes + positioning 3s + cutting 5s + other time 44s) |