Wireless transmission steel bar ultrasonic flaw detector

Steel bar is a conventional product with high density, moderate noise. The system is suitable for automatic detection of internal and external defects of various steel bars. The principle of ultrasonic flaw detection is that when the ultrasonic wave is coupled into the steel bar by water, the incident propagation will cause the ultrasonic reflection when there is a defect in the bar. The ultrasoni...

Next OnlineProduct introduction

Probe configuration

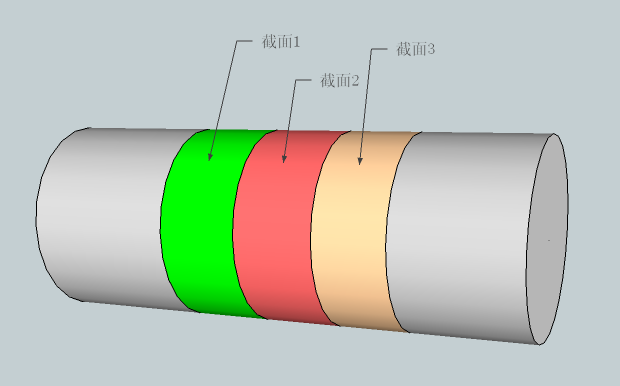

1. Probe Configuration on Spindle Section 1

There are two probe regulators on section 1, 180 degrees apart. Each regulator is equipped with a two-channel combination of ultrasonic line focus probes, and the transverse wave incident clockwise.

Detection Defects: Clockwise Detection of Subcutaneous Defects of Round Steel

Central Frequency: 5.0MHz + 10%

Coupling mode: water immersion method

Quantity: Two groups of probes, each containing two combinations of wafers, the two groups of probes are distributed in the circumferential direction of the workpiece, with an interval of 180 degrees, on the same cross-section. There are four independent channels.

2. Probe Configuration on Spindle Section 2

There are two probe regulators on section 2, each 180 degrees apart. Each regulator is equipped with a two-channel combination of ultrasonic line focus probes, longitudinal wave incidence.

Testing defects: metallurgical defects inside steel bars.

Detection range: central cross-hole.

Central Frequency: 5.0MHz + 10%

Coupling mode: water immersion method

Quantity: Two groups of probes, each consisting of two combinations of wafers, are distributed in the circumferential direction of the workpiece with an average interval of 180 degrees and four independent channels on the same cross-section.

3. Probe Configuration on Spindle Section 3

There are two probe regulators on section 3, each 180 degrees apart. Each regulator is equipped with a two-channel combination of ultrasonic line-focus probes, which incident transverse waves counterclockwise.

Detection Defects: Detection of Subcutaneous Defects of Round Steel Counterclockwise

Central Frequency: 5.0MHz + 10%

Coupling mode: water immersion method

Quantity: Two groups of probes, each consisting of two combinations of wafers, are distributed in the circumferential direction of the workpiece with an average interval of 180 degrees and four independent channels on the same cross-section.

1. Probe Configuration on Spindle Section 1

There are two probe regulators on section 1, 180 degrees apart. Each regulator is equipped with a two-channel combination of ultrasonic line focus probes, and the transverse wave incident clockwise.

Detection Defects: Clockwise Detection of Subcutaneous Defects of Round Steel

Central Frequency: 5.0MHz + 10%

Coupling mode: water immersion method

Quantity: Two groups of probes, each containing two combinations of wafers, the two groups of probes are distributed in the circumferential direction of the workpiece, with an interval of 180 degrees, on the same cross-section. There are four independent channels.

2. Probe Configuration on Spindle Section 2

There are two probe regulators on section 2, each 180 degrees apart. Each regulator is equipped with a two-channel combination of ultrasonic line focus probes, longitudinal wave incidence.

Testing defects: metallurgical defects inside steel bars.

Detection range: central cross-hole.

Central Frequency: 5.0MHz + 10%

Coupling mode: water immersion method

Quantity: Two groups of probes, each consisting of two combinations of wafers, are distributed in the circumferential direction of the workpiece with an average interval of 180 degrees and four independent channels on the same cross-section.

3. Probe Configuration on Spindle Section 3

There are two probe regulators on section 3, each 180 degrees apart. Each regulator is equipped with a two-channel combination of ultrasonic line-focus probes, which incident transverse waves counterclockwise.

Detection Defects: Detection of Subcutaneous Defects of Round Steel Counterclockwise

Central Frequency: 5.0MHz + 10%

Coupling mode: water immersion method

Quantity: Two groups of probes, each consisting of two combinations of wafers, are distributed in the circumferential direction of the workpiece with an average interval of 180 degrees and four independent channels on the same cross-section.

Defect detection standard

Ultrasound Testing Method for Forged Rolled Steel Bars GB/T4162-2008

Performance

|

Channel number |

12 channels |

|

Flaw detection speed |

30m/min |

|

Total gain |

100dB,side size 0.5dB |

| Operation mode |

Single-probe transmitting, receiving or double-probe transmitting and receiving respectively |

|

Sensitivity margin |

≥50dB |

| Resolving rate |

≥26dB |

|

Dynamic range |

≥30dB |

|

Scan range |

0~5000mm |

|

Frequency range |

0.5~20MHz |

|

Sampling range |

250MHz |

|

Repetition rate |

Single channel 100Hz~4KHz adjustable |

|

Vertical linearity |

≤2% |

|

Horizontal linearity |

≤1% |

|

Detection mode |

Full wave, positive half wave and negative half wave |

|

Gate setting |

Each channel has three gates, A and B are defective gates and C are interface tracking gates |

|

Alarm indication |

Color Display and Sound Alarm of A, B and C Gate Alarm in Each Channel |

|

Delayed alarm |

Two paths, delay time 0.1-10S, step 0.1S |

|

Waveform storage, unlimited number, waveform playback, printing and report generation |